PPI, CORP.

039-133-241 VW Bus & Porsche 914 Air Intake Boot - 1.7L 1.8L 2.0L

039-133-241 VW Bus & Porsche 914 Air Intake Boot - 1.7L 1.8L 2.0L

Couldn't load pickup availability

Air Intake Boot – 039-133-241

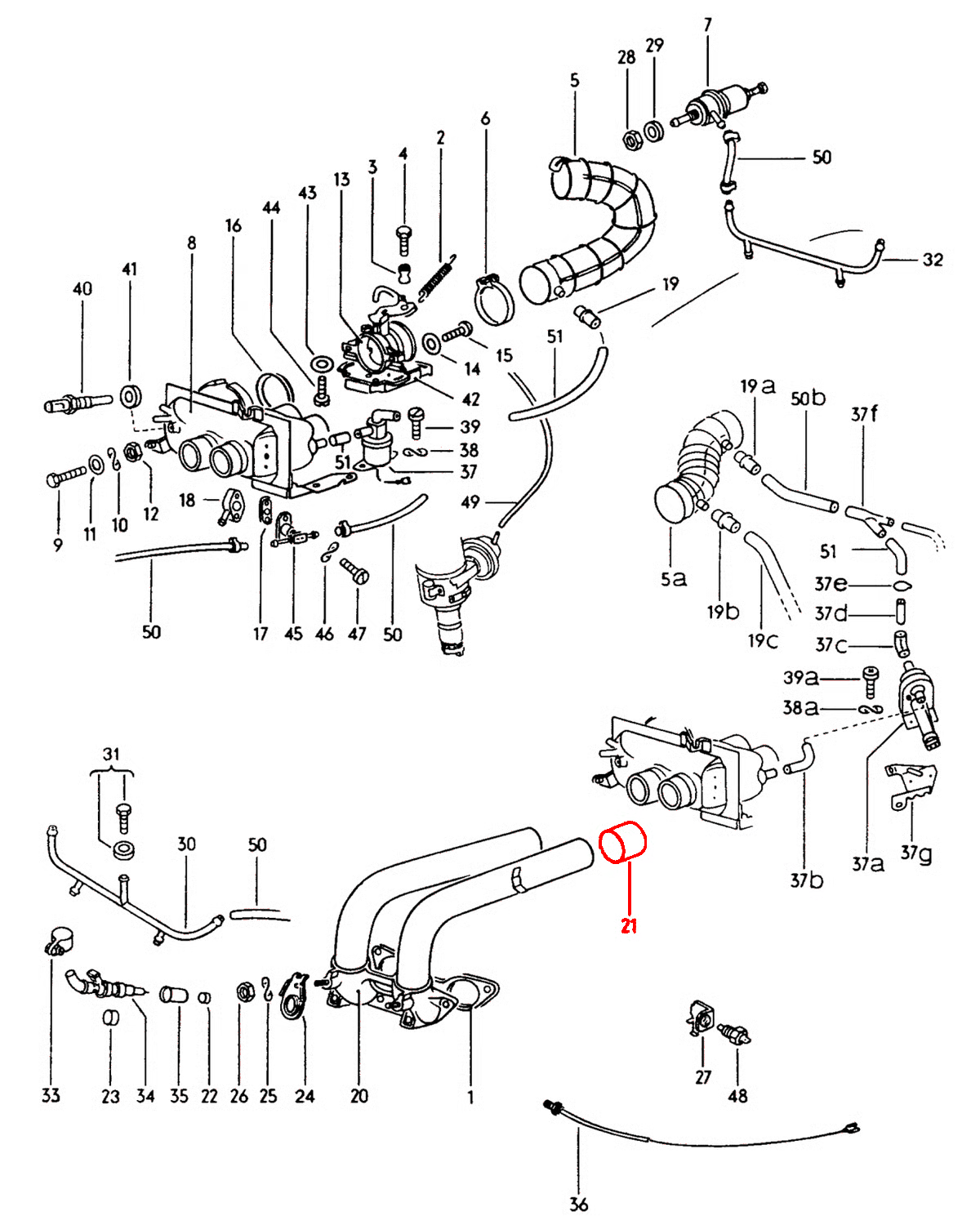

The 039-133-241 is a critical air induction component for vintage air-cooled and early water-cooled Volkswagen and Porsche engines. This flexible rubber bellows connects the Air Flow Meter (AFM) to the intake manifold. It is designed to bridge the gap between the stationary air box and the vibrating engine, ensuring that all air entering the cylinders is properly metered by the fuel injection system.

In systems like L-Jetronic and AFC, this boot is the most common source of "unmetered air" leaks. Because it sits after the sensor, any air entering through a crack is not accounted for by the ECU, leading to a lean fuel mixture. This typically results in a hard start, a "hunting" or erratic idle, and significant power loss under load.

Detailed Vehicle Compatibility

Porsche 912:

-

1976

Porsche 914:

-

1973, 1974, 1975, 1976

VW 412:

-

1974

VW Transporter (Bus):

-

1972, 1973, 1974, 1975, 1976, 1977, 1978, 1979, 1985

VW Vanagon:

-

1980, 1981, 1982, 1983, 1984, 1985

Product Highlights & Features

-

Direct Air-Cooled Fitment: Engineered specifically for the unique geometry of the Type 4 and late Type 1 fuel-injected engines.

-

Flexible Bellows Structure: The multi-ribbed design absorbs engine torque and vibration, protecting the delicate plastic internals of the Air Flow Meter.

-

High-Grade Elastomer: Built from heat-stabilized rubber that resists the "drying out" effect caused by the high operating temperatures of air-cooled engine bays.

-

Vacuum Integrity: Provides a 100% airtight seal to ensure the AFM sends accurate voltage signals to the fuel injection computer.

Technical Specifications

-

Part Number: 039-133-241

-

Interchange: 039133241

-

Engine Application: 1.7L, 1.8L, 1.9L, 2.0L

-

System Type: Bosch L-Jetronic / Digijet / Digifant

Installation & Maintenance Tips

-

Inspect the Ribs: When diagnosing a poor idle, remove this boot and bend the rubber. Cracks often hide in the "valleys" of the bellows and are only visible when the boot is flexed.

-

Avoid "Worm" Clamps: Use smooth-band fuel injection clamps if possible. Standard serrated worm-gear clamps can bite into the old or new rubber over time, creating a fresh leak point.

-

Port Alignment: Ensure the auxiliary ports (for the idle air control or breather) are fully seated and clamped. A loose breather hose on the side of this boot is a frequent cause of "ghost" vacuum leaks.

-

No Sealant Needed: Do not use RTV or silicone on the flanges. The rubber is designed to seal dry against the clean metal or plastic surfaces of the intake and AFM.

039133241

Share